The finish on a steel barrier does more than change how it looks. It determines how well it resists corrosion, how long it lasts, and how much maintenance it needs over time.

At CT Safety Barriers, every Armco barrier is made in the UK and finished to exacting standards. We handle the entire process from fabrication to final coating. That’s how we guarantee strength, safety, and a finish that stands up to daily wear.

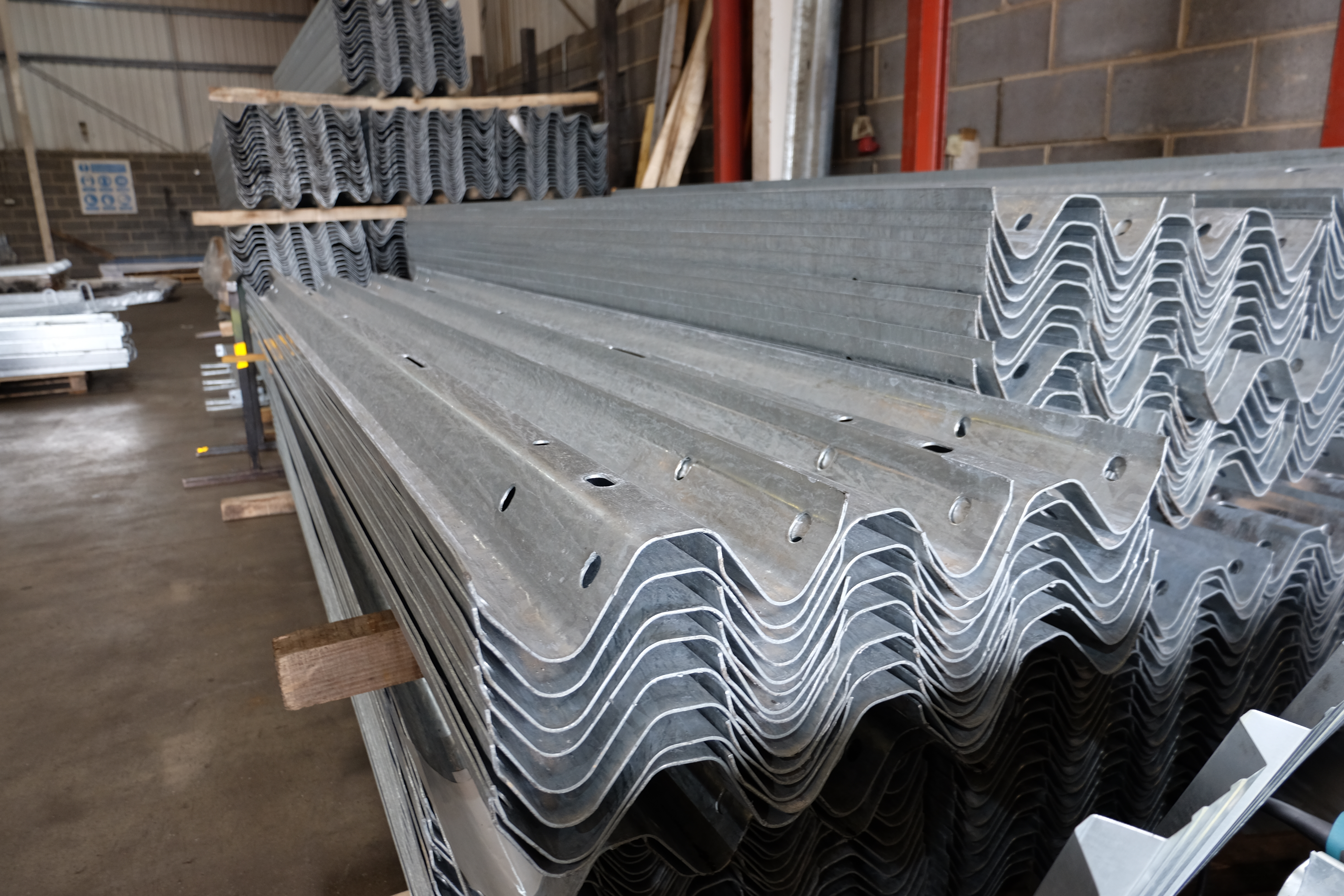

What Is Galvanised Steel?

Hot-dip galvanising involves immersing cleaned steel in molten zinc. As it cools, the zinc bonds with the metal surface, forming a tough protective layer. Over time, this layer wears away to prevent the underlying steel from rusting.

Key advantages of galvanised steel barriers

- Excellent rust resistance, even in harsh or coastal conditions

- Minimal maintenance once installed

- Strong, impact-tolerant surface that ages predictably

- Long service life, often 25 years or more outdoors

How thick is the galvanised steel coating?

Typical galvanising adds around 85 microns of zinc. For coastal or heavy-industrial settings, a thicker deposit may be applied to meet BS EN ISO 1461 standards. Each micron adds measurable protection time, making galvanising the benchmark for outdoor durability.

Galvanised steel is best suited for…

- Loading bays and service yards

- Construction sites and depots

- Marine and coastal facilities

- Outdoor car parks and roadside barriers

What Is Powder-Coated Steel?

Powder coating uses an electrostatic charge to apply a fine, dry powder to the metal barrier or barrier part. The coated item is then cured in an oven, producing a hard, continuous film. The finish can range from matt to gloss, with hundreds of colour options available.

Key advantages of powder coating barriers

- Broad colour choice for visibility, zoning, or branding

- Resistant to damage and wear

- Smooth, even surface with no drips or runs

- Better UV stability than traditional liquid paints

Technical detail

A typical powder coat is 60 to 120 microns thick, depending on colour and environment. Polyester powders work best for outside use, whereas epoxy-polyester hybrids suit indoor or semi-sheltered areas.

Powder coasted barriers are best suited for

- Indoor or covered car parks

- Warehouses and logistics centres

- Public areas where colour or appearance matters

- Sites with colour-coded safety zones

Galvanised vs Powder-Coated – Key Differences

| Feature | Galvanised finish | Powder coating |

| Protection | Excellent corrosion defence, especially outdoors | Strong impact and UV performance, dependable indoors and semi-covered areas |

| Appearance | Matt silver-grey, practical | Smooth, coloured, customisable |

| Maintenance | Very low, zinc layer self-sacrifices over time | Occasional touch-ups may be needed in high-traffic areas |

| Cost | Often higher upfront, pays back in harsh settings | Typically cost-effective, varies by colour and prep |

| Best use | Harsh outdoor or coastal conditions | Indoor spaces, visual signalling, branded sites |

You can also combine both, choosing powder-coated, galvanised steel. In this case, the barriers will be galvanised first to protect them from rust, and then colour will be added for visibility and a smart finish.

Which Finish Should You Choose For Your Barriers?

The best coating or finish for an Armco barrier depends on the environment you’re installing it. You should choose:

- Galvanised for long-term protection in exposed or coastal areas.

- Powder coating when colour, wayfinding, or a clean look takes priority, especially indoors.

- Both if you want the durability of galvanising and the clarity of colour in one package.

All finishing is done in the UK, which means our lead times are short and quality checks are consistent.

Get in Touch

Both options are reliable, and both meet safety and compliance expectations. The right answer depends on where the barrier lives and what you need it to do. If you want a sounding board, we are happy to help you weigh up the trade-offs.

With CT Safety Barriers, you’re in safe, local hands.

Call us on (01977) 666 818 or send an email to sales@ctsafetybarriers.co.uk.